In the world of electrical engineering, power distribution is critical for residential, commercial, and industrial applications. Two primary types of power distribution are single-phase and three-phase. Single-phase power is commonly used in household systems, while three-phase power is widely employed in commercial and industrial settings. But why is three-phase power often the preferred choice for large-scale applications?

In this article, we’ll explore the advantages of three-phase power over single-phase power, discussing how it improves efficiency, reliability, and performance in various applications. We’ll also look at some disadvantages of three-phase power to provide a well-rounded view.

Introduction to Single-Phase and Three-Phase Power Systems

Before delving into the advantages, it’s essential to understand the basic differences between single-phase and three-phase power systems:

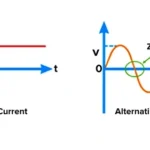

- Single-Phase Power: In single-phase power, there is one alternating current (AC) waveform. This type of power has a single voltage that alternates between a positive and negative cycle. Single-phase power is generally used for small household appliances and systems, where power requirements are relatively low.

- Three-Phase Power: In three-phase power, three alternating currents are generated with a 120-degree phase shift between each phase. This configuration provides a continuous flow of power, which results in higher efficiency, stability, and power output. Three-phase power is typically used in commercial and industrial settings, where machines and equipment demand high power levels.

Now that we have a foundational understanding of single-phase and three-phase systems, let’s examine the many advantages that three-phase power offers over single-phase power.

Advantages of Three-Phase Power Over Single-Phase Power

1. Increased Power Efficiency

One of the most significant advantages of three-phase power is its increased efficiency in delivering electricity. In single-phase systems, power delivery is pulsating, meaning there are moments when power levels drop to zero. This fluctuation in power delivery can lead to inefficiencies, especially for high-power applications.

In contrast, three-phase power provides a continuous flow of energy. Since the three-phase system uses three alternating currents that are 120 degrees out of phase with each other, the power delivered is more stable and consistent. This results in better efficiency and makes three-phase power ideal for industrial applications that require a constant power supply, such as heavy machinery, motors, and other high-load equipment.

2. Higher Power Density

Three-phase power allows for greater power density, meaning it can deliver more power with fewer conductors. A three-phase system can transmit up to 1.73 times the power of a single-phase system using the same amount of current. This power density is particularly advantageous for large-scale applications, as it reduces the need for thick or multiple conductors to handle the power requirements.

Higher power density also enables three-phase systems to support more equipment and machinery per circuit, making it suitable for factories, manufacturing plants, and other facilities that require significant amounts of power.

3. Balanced Load

In a single-phase system, power delivery is unbalanced because the load is powered by a single alternating current. This imbalance can lead to fluctuations and may reduce efficiency, especially when multiple devices are drawing power simultaneously.

Three-phase systems distribute the load across three conductors, which helps balance the power draw. This balance results in a smoother, more stable operation of connected equipment and reduces wear and tear on the electrical infrastructure. The balanced load also improves efficiency and minimizes the risk of overloading circuits, which is crucial in environments with a high power demand.

4. Reduced Conductor Material and Cost Savings

A three-phase system requires fewer conductors to transmit the same amount of power as a single-phase system. For instance, in a three-phase system, only three conductors are required (plus a neutral conductor in certain configurations), compared to the need for two conductors in a single-phase system to achieve the same power output.

Since conductor material, such as copper or aluminum, can be expensive, using fewer conductors in a three-phase system can lead to significant cost savings in installation and maintenance. For industries or commercial applications that require extensive wiring, this reduction in conductor material can result in considerable financial savings over time.

5. Improved Motor Performance and Efficiency

Three-phase power systems provide a distinct advantage for motors, particularly in industrial applications. Motors powered by three-phase systems are more efficient and produce smoother rotational motion. Three-phase motors experience a constant rotating magnetic field, which leads to consistent torque, fewer vibrations, and lower operating temperatures.

In contrast, single-phase motors experience pulsating power, which can cause vibrations and uneven motion. These factors make single-phase motors less efficient and more prone to overheating. Three-phase motors are thus more durable, have a longer lifespan, and require less maintenance, which is essential in settings where motors operate continuously.

6. Scalability for Industrial Applications

Three-phase power is inherently more scalable than single-phase power, making it ideal for large-scale applications. Industrial facilities, data centers, and manufacturing plants often require high power levels to support various types of machinery and equipment. Three-phase power systems can handle these demands with ease, providing a stable, reliable, and scalable power supply.

Additionally, if a facility expands or adds more equipment, it’s easier to scale a three-phase power system to meet the new demands without significant upgrades. This flexibility makes three-phase power more suitable for businesses with growth potential, as it allows for future scalability.

7. Less Electrical Loss and Heat Generation

Three-phase systems generate less electrical loss and heat compared to single-phase systems. This reduced energy loss is particularly beneficial in applications requiring long-distance power transmission, as the reduced heat and power loss result in better energy efficiency.

The lower heat generation in three-phase systems also contributes to the longevity of electrical equipment, as components experience less thermal stress. This advantage translates into reduced maintenance costs and less frequent replacements, which is crucial in industrial settings where equipment uptime is a priority.

8. Compatibility with High-Power Equipment

Many heavy-duty industrial machines and equipment are designed to operate on three-phase power due to its efficiency and stability. Equipment such as large motors, pumps, compressors, and HVAC systems require the balanced and continuous power that three-phase systems provide. Powering such high-demand equipment with a single-phase system would lead to frequent overloads, inefficiency, and potential damage.

Three-phase systems are also better suited to handle sudden surges or changes in power demand, providing the necessary robustness and reliability for high-power applications.

Disadvantages of Three-Phase Power Compared to Single-Phase Power

While three-phase power offers numerous advantages, there are some disadvantages when compared to single-phase power:

1. Higher Installation Costs for Small-Scale Applications

The installation of a three-phase power system can be more expensive than a single-phase system, particularly for small-scale or residential applications. Three-phase power requires specialized wiring, distribution boards, and circuit breakers, which can add to the initial setup costs. For small residential properties or facilities with low power demands, the benefits of three-phase power may not justify the higher installation expenses.

In such cases, single-phase power is usually more cost-effective, as it provides adequate power for household appliances and small devices without the need for specialized equipment.

2. Complex Maintenance and Troubleshooting

Three-phase systems are inherently more complex than single-phase systems, which can make maintenance and troubleshooting more challenging. Technicians working with three-phase systems require specialized knowledge and skills to address issues, and maintenance costs may be higher due to the complexity of the setup.

In contrast, single-phase systems are simpler and easier to troubleshoot, making them more convenient for residential and small-business users who may not have access to specialized electrical professionals.

3. Not Required for Low-Power Applications

For low-power applications, such as standard household appliances, lighting, and small electronic devices, three-phase power may be unnecessary. Single-phase power is sufficient for these devices, and using a three-phase system would add unnecessary complexity and cost.

Three-phase power is generally recommended for high-demand industrial and commercial applications. In settings where the power demand is minimal, single-phase systems provide a simpler, more economical solution.

4. Space Requirements for Equipment

Three-phase power systems often require larger, specialized equipment such as transformers, distribution boards, and breakers. This equipment can take up additional space, which may not be ideal in settings where space is limited. Single-phase systems, by comparison, require less equipment and are more compact, making them better suited to locations with limited space.

This space requirement may make three-phase systems less practical for small businesses or residential areas where available space is a concern.

Conclusion

Three-phase power has numerous advantages over single-phase power, making it the preferred choice for industrial, commercial, and large-scale applications. Its ability to deliver continuous, balanced, and high-density power enhances efficiency, reduces electrical loss, and improves the performance of heavy machinery and equipment. Three-phase power systems also allow for greater scalability, making them well-suited for environments with high power demands.

However, three-phase power is not ideal for every situation. The higher installation costs, complex maintenance requirements, and additional space needed for equipment make it less practical for low-power applications and residential settings, where single-phase power remains the economical and efficient choice.

In summary, while single-phase power is well-suited for residential and small-scale uses, three-phase power offers the performance, reliability, and efficiency needed for demanding industrial and commercial applications. Understanding the strengths and limitations of each system enables businesses and consumers to choose the best power solution based on their specific requirements.